Plastics play a key role in the construction industry because of their lightweight, durable, and malleable properties, and are widely used in many fields such as heat insulation, insulation, pipes, and window frames. However, the use of plastics faces sustainability and environmental pressures. Global supply chain volatility and raw material price changes also pose challenges to its cost and availability. In the continuous development and evolution of the construction industry, the plastic material industry needs to continue to innovate and improve environmental protection and application performance to adapt to the increasing market demand for sustainable, safe, and efficient building materials.

PE geomembrane is widely used in water conservancy engineering, road engineering, environmental protection, landfill, mining, and other fields, for seepage prevention, waterproofing, isolation and protection. With the gradual improvement of technical standards and quality requirements for geomembranes in various industries, manufacturers are required to use more high-quality raw materials to optimize the physical properties of products and improve the impermeability and durability of PE geomembranes.

We produce high-quality recycled polyethylene through strict quality control to ensure that the PE geomembrane you produce is more uniform and stable, ensuring the competitiveness of your products.

We produce high-quality recycled polyethylene through strict quality control to ensure that the PE geomembrane you produce is more uniform and stable, ensuring the competitiveness of your products.

We produce high-quality recycled polyethylene through strict quality control to ensure that the PE geomembrane you produce is more uniform and stable, ensuring the competitiveness of your products.

We produce high-quality recycled polyethylene through strict quality control to ensure that the PE geomembrane you produce is more uniform and stable, ensuring the competitiveness of your products.

We produce high-quality recycled polyethylene through strict quality control to ensure that the PE geomembrane you produce is more uniform and stable, ensuring the competitiveness of your products.

Our high-quality, stable-performance recycled plastic products can meet your needs for film products made of different materials.

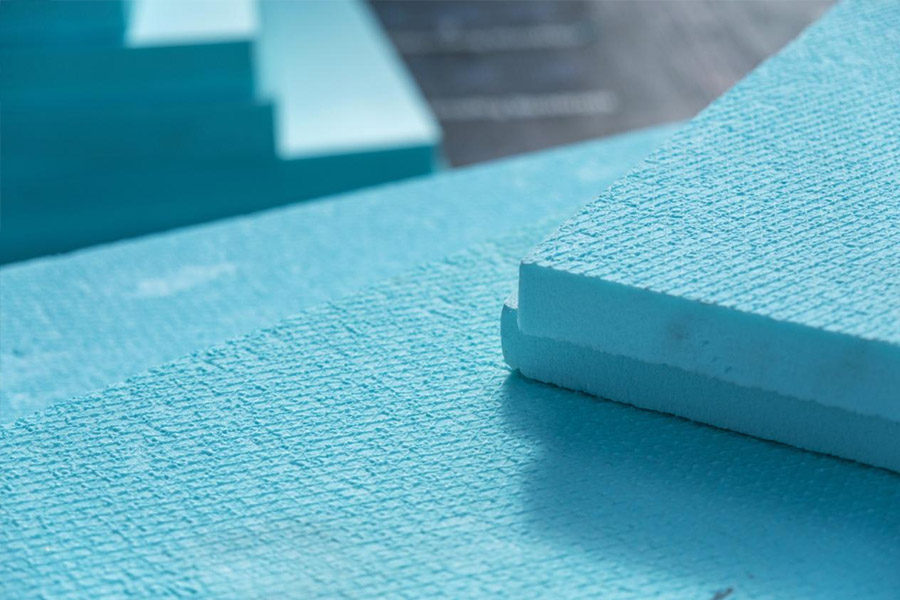

Extruded panels are often used in the construction field for wall insulation, roof insulation, floor insulation, etc. Under the trend of sustainable building and energy saving and environmental protection, enterprises pay more attention to environmental protection issues in the production process and begin to use recycled plastics for the production of extruded panels to promote the sustainable development of the industry.

Advanced production technology, production equipment, and standardized production processes have formed a complete production management system, ensuring our strong manufacturing capabilities, excellent production delivery capabilities, and market competitiveness.

If you need plastics with good toughness, recycling and environmentally friendly properties, our products can meet your sheet product needs.

PE pipe is an ideal pipe material because of its lightweight, corrosion resistance, and easy installation. In construction, it is widely used in water supply, drainage, gas transmission, and other fields. With the continuous development and innovation of PE pipe manufacturing technology, new PE pipe products have gradually emerged, including antibacterial PE pipes, high-temperature and high-pressure PE pipes, etc., to meet different uses and environmental needs.

Our advanced recycled particle modification process can be customized according to your individual needs to meet the different patterns, shapes, sizes, performance and other requirements of your products.

Our recycled plastic products meet the needs of many of today’s injection molded products and can be used in a wide range of industries.

PE sunshade net is mainly used for sunshade and sun protection in construction and urban greening projects. A variety of color and density options exist on the market to suit the needs of different environments. To have better weather resistance, UV resistance linearity, environmental protection, and other properties, it is necessary to use raw materials that meet their own needs.

Advanced production technology, production equipment, and standardized production processes have formed a complete production management system, ensuring our strong manufacturing capabilities, excellent production delivery capabilities, and market competitiveness.

Our recycled raw material particles can meet your application needs for fiber products

The wide application of PS BMC group membrane materials is mainly based on its molding performance, mechanical properties, chemical stability and cost-effectiveness. In different fields, PS BMC group membrane materials can provide a variety of solutions to meet the needs of different applications. The plastics industry has been working hard to promote technological innovation to improve material performance, production efficiency and environmental friendliness. Manufacturers of PS BMC group membrane materials may innovate in material formulas, production processes, etc.

Our advanced recycled particle modification process can be customized according to your individual needs to meet the different patterns, shapes, sizes, performance and other requirements of your products.

Our mature modification technology meets your personalized customization of raw materials