I. Introduction

The environmental problem of waste is a big issue worldwide! Every year tons of plastic get dumped in landfills and oceans causing pollution and damaging nature’s balance. Enough not all plastics are the same when it comes to recycling. It depends largely upon their composition and properties as well, as the recycling facilities available. In this blog post, we’ll delve into the seven commonly recycled plastics to shed light on sustainable practices and ways to reduce waste effectively.

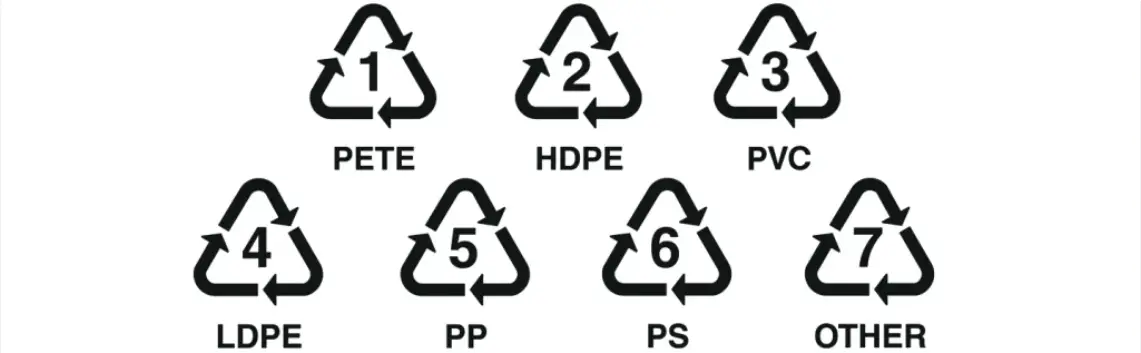

II. The Top Seven Recycled Plastics

There are seven types of plastics (codes 1-7), each classified based on their resin identification codes and possessing characteristics and recycling capabilities. Although all seven types can be recycled, technically speaking, the effectiveness and scope of recycling vary significantly. The upcoming sections will offer in-depth insights focusing on PET, HDPE, LDPE, LLDPE, PP, and PS due to their higher rates of recycling and widespread use in industries.

A. PET (Recycling Code 1)

PET is widely known as the most commonly recycled type of plastic on a global scale due to its frequent usage in beverage bottles and food containers, as well as clothing fibers, which greatly adds to its impressive recycling rate. Its clear appearance, weight, and sturdy nature make it a top choice for substituting heavier materials such as glass in packaging.

PET recycling usually includes gathering the plastic material and separating it based you’re sorting it out, washing it off, and then melting it down to form pellets. These small bits are later utilized in creating fresh PET items, like containers, apparel materials, or various goods; however, there are still difficulties ahead.

- Contamination: Food residue or other contaminants can reduce rPET quality, limiting its reusability.

- Color Consistency: Recycled PET often has inconsistent color, requiring further processing for uniform coloring in new products.

Despite facing challenges, the need for rPET continues to grow as people become more environmentally conscious and regulations push for the use of recycled materials. Improvements in sorting technologies and methods to neutralize colors are making rPET better in quality and consistency. Mechanical recycling demonstrates the ability of PET to undergo recycling continuously without compromising quality standards. Studies on life cycles reveal that recycling PET offers benefits by reducing energy consumption and greenhouse gas emissions in comparison, to producing new PET materials.

Application:

- Packaging: RPET finds application in crafting fresh beverage bottles and food containers along with various packaging materials essential for transportation and storage durability requirements, for packaging materials. With its tensile strength and stable dimensions RPET proves ideal for both food-grade and non-food-grade packaging purposes.

- Textiles: Recycled PET is used to manufacture fibers for clothing, carpets, and other textiles. It can be blended with other fibers to create materials with specific properties.

- Automotive: RPET can be found in automotive components such as interior fabrics, seat fabrics, headliners, grilles, and bumpers due to its strength, durability, and temperature resistance.

- Construction: rPET can be used in construction materials like insulation, roofing membranes, and sound barriers. It can also be used as a fine aggregate in concrete.

- Other applications: rPET can be used in electronic components, medical devices, medical tubing, and diagnostic tools. It can also be converted into hydrogel adsorbents.

B. HDPE (Recycling Code 2)

High-density polyethylene (HDPE), commonly found in milk containers and cleaning product bottles among rigid packaging items, is frequently recycled due to its sturdy nature and ability to withstand chemicals effectively.

HDPE is completely recyclable through a process that involves shredding your use of HDPE products contributes to its significant recycling rate. Melting and pelletizing. This results in top-grade recycled HDPE that can be applied in ways such as pipes and plastic lumber and even in some food packaging options.

The realm of recycled HDPE materials like PET plastic faces contamination issues, which impact the quality and usability of the final product significantly. RHDPE recycled pellets boast colors like dark green or white and demonstrate high purity levels and great processability. Pointing to the potential of recycled HDPE in diverse uses such, as packaging.

Application:

- Bottles and Containers: Recycled HDPE (rHDPE) is commonly used to make new bottles for non-food products, such as detergents, cleaning supplies, and personal care items. It is also used for other types of containers due to its durability and chemical resistance.

- Pipes: rHDPE is suitable for manufacturing non-potable pipes for irrigation and drainage systems.

- Building Materials: rHDPE is used in the production of composite lumber, decking, and other construction products.

C. PVC or V (Recycling Code 3)

PVC or polyvinyl chloride is a type of plastic widely used in products like pipes and flooring as well as window frames Recycling PVC presents difficulties when compared to materials, like PET or HDPE because of its intricate structure and the additional substances added during production. It’s worth noting that several recycling centers do not handle PVC materials.

D. LDPE/LLDPE (Recycling Code 4)

LDPE and LLDPE are types of plastics commonly utilized in the production of plastic films and bags, as well as shrink wraps; however, their pliability poses difficulties when it comes to traditional mechanical recycling processes.

Application:

- Film and Bags: Recycled LDPE (rLDPE) is used to create new plastic films, bags, and bin liners. It can also be used in agricultural film.

- Lower Value Products: Due to the challenges in recycling, rLDPE/LLDPE is often downcycled into lower-value products such as composite lumber, garbage bags, and other less demanding applications.

- Other:rLDPE is used in applications such as trash cans and floor tiles.

Recycling plastics like LDPE and rLDPE comes with its set of challenges when compared to recycling PET or HDPE because of their flexible nature which can make sorting and processing more complex and result in the creation of lower quality products through downcycling methods. There are efforts to improve recycling techniques for LDPE and LLDPE plastics while also exploring chemical recycling methods as part of sustainability initiatives in the industry. However, the use of recycled LDPE and HDPE materials in food packaging faces obstacles such as concerns about permeability. Ensuring compliance, with relevant regulations.

E. PP (Recycling Code 5)

Polypropylene (PP), a utilized plastic found in a range of items such as containers and packaging materials as well as fibers, encounters challenges akin to those of HDPE when it comes to recycling in terms of effectiveness and the quality of the result.

PP recycling usually includes melting and forming pellets to generate material, for producing PP items. However, the main obstacle that persists is contamination.

Application:

- Automotive Parts: Recycled PP (rPP) is used in automotive parts such as bumpers, interior trims, and battery casings.

- Textiles and Fibers: rPP can be recycled into fibers for use in carpets, clothing, and other textiles.

- Packaging: rPP is used to make non-food packaging items such as bottle caps, straws, and containers.

- Consumer Goods: rPP is used to produce a variety of consumer goods, including toys, storage boxes, and household items.

F. PS (Recycling Code 6)

Polystyrene (PS) commonly found in cups and packaging items is recycled less compared to plastics due to factors like additives present in the material and the delicate nature of certain PS products that necessitate specific recycling facilities.

PS, while recyclable, is more challenging to recycle than PET or HDPE due to the difficulties in separating PS grades and consistently producing high-quality recycled materials.

Application:

- Construction: Recycled PS (rPS) can be used for insulation materials, often in the form of expanded polystyrene (EPS) foam.

- Consumer Goods:rPS is sometimes used in the production of consumer goods and office supplies.

G. OTHER (Recycling Code 7)

This group comprises types of plastics like nylon (PA), ABS, and TPE materials with various chemical compositions that make recycling challenging and complex processes involved, leading to low recycling rates due to infrastructure limitations and specific processing needs.

III. INTCO: A Reliable Recycled Plastic Supplier

INTCO adopts a strategy that covers various elements of the recycling procedure.

- Global Sourcing & Supply Management: INTCO’s global network of recycling centers ensures a consistent supply of recycled raw materials, mitigating some challenges associated with inconsistent feedstock quality and quantity.

- End-to-End Traceability: INTCO emphasizes traceability throughout the entire supply chain, from raw material recovery to final product distribution. This transparency helps build trust and confidence in the quality and sustainability of their recycled plastics, addressing concerns about the quality and variability of recycled materials.

- Process Design Capability: INTCO uses cutting-edge particle modification technology and customizes solutions to optimize production processes, reducing costs and improving efficiency. This indirectly addresses many recycling challenges associated with processing, such as degradation. Their process recommendations and focus on advanced production processes would impact all five plastics by streamlining production.

- Manufacturing Production Capacity: INTCO’s advanced production processes and state-of-the-art equipment ensure high-quality output. This capability reduces the limitations associated with lower-quality recyclates from insufficient technology. Their high production capacity directly impacts the availability and affordability of recycled plastics.

- Quality Management System: INTCO integrates cutting-edge processes and standardized procedures into its production management system, ensuring product quality.

To sum it up nicely, although all seven primary types of plastic can be recycled in theory, improvements in recycling facilities and methods along with a prioritization of recyclable materials such as PET and HDPE are crucial in tackling the worldwide plastic waste issue and creating a sustainable tomorrow. The details shared here underscore the importance of raising awareness and enhancing recycling habits to reduce the repercussions of plastic waste.