The packaging sector is always. Focusing more on sustainability and environmental awareness these days. Recycled high-density polyethylene ( rHDPE ) pellets have become a choice as they are versatile and environmentally friendly making them suitable for various packaging uses.

What are rHDPE Pellets?

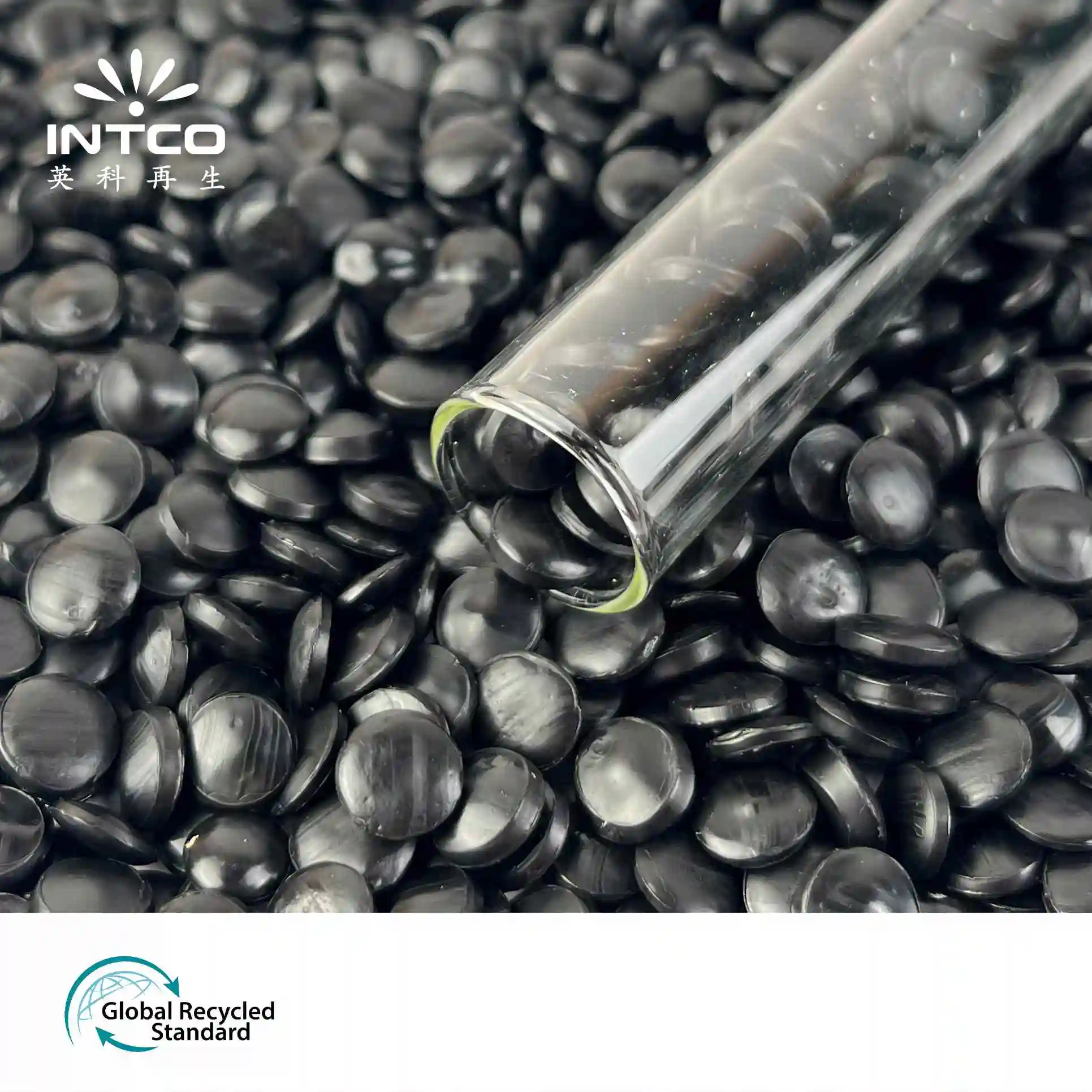

rHDPE pellets are granules crafted from recycled HDPE plastic scraps which are widely recognized for their robustness and chemical resistant properties in the thermoplastic polymer realm. The creation of these pellets entails gathering and organizing waste fragments followed by washing and shredding them into smaller bits before melting and reshaping them into pellets. These pellets play a role as foundational materials for producing an array of goods while presenting an eco-friendly substitute to new HDPE materials.

Top 5 Packaging Applications of rHDPE Pellets

The use of rHDPE pellets has been a game changer in the packaging sector by offering eco solutions without any trade-offs in effectiveness or performance levels. Here are five critical areas where rHDPE pellets are generating an influence.

Bottles and Containers

rHDPE is used for plastic bottles and containers for water, milk, juice, and cleaning supplies. Its non-leaching properties ensure safe food and beverage packaging. It’s ideal for household cleaning products, motor oil, and antifreeze, because it’s durable and chemically resistant.

Retail Bags and Film Wrap

Retail bags and film wraps play a role in packaging and moving items within the retail industry. The utilization of rHDPE pellets to produce these items provides a durable option compared to conventional plastic films. The incorporation of rHDPE in bags and film wrap contributes to the reduction of plastic waste and supports a circular economy through the implementation of recycled materials.

Caps and Closures

Seals and lids are used in packaging to maintain the safety and reliability of the product. Bottle and container caps and closures are produced from rHDPE pellets to offer a durable and economical option. Application of rHDPE in caps and closures decreases the demand for plastics and lowers the environmental footprint.

Industrial Liners

In industries industrial liners are employed to safeguard and confine products throughout storage and transportation activities. rHDPE pellets are chosen for crafting these liners because of their resilience to chemicals and enduring nature. These liners are capable of enduring environments and averting leaks to maintain the secure management of industrial substances.

Buckets and Totes

Containers like buckets and bins store and transport items like paints, food ingredients, and chemicals. rHDPE pellets create durable, impact-resistant buckets and totes, reducing single-use packaging and waste.

Advantages of rHDPE Chips in Packaging

Durability and Strength

rHDPE offers high tensile strength and impact resistance, ensuring packaging withstands handling and transportation. This durability reduces content damage risk and minimizes waste from broken packaging.

Chemical Resistance

rHDPE resists chemical solvents and is ideal for packaging household cleaners, industrial chemicals, and food items. It ensures packaging integrity, maintaining product quality and safety.

UV Resistance

rHDPE is resistant to UV rays which help preserve the toys from being damaged or discolored by the sun’s rays.

Sustainability

One of the best advantages of rHDPE is that it is environmentally friendly. By using recycled content, you can reduce the demand for virgin plastics and the impact of plastic production on the environment. rHDPE also supports a circular economy since it keeps plastic waste circulating and not in landfills.

Cost-Effectiveness

Using rHDPE is a budget choice that provides a viable substitute for new plastics in terms of cost-effectiveness.

Future Trends in rHDPE Chips Packaging

The outlook for rHDPE packaging looks bright as advancements continue and there’s a growing interest in eco options. Let’s explore some important developments to keep an eye out for.

Innovations in Recycling Technologies

Improvements in recycling technologies are enhancing the quality and accessibility of rHDPE pellets. These advancements are making it possible to produce rHDPE with characteristics of new plastics expanding its uses in different areas.m

Increasing Demand for Sustainable Packaging

With the rising interest in eco packaging among consumers today’s businesses are facing greater expectations to incorporate sustainable materials such as rHDPE into their packaging solutions. This trend towards sustainability has led to a surge in both investment and creativity in developing rHDPE packaging options.

Advancements in rHDPE Material Properties

Ongoing research and development focus on further enhancing the physical properties of rHDPE, such as strength, flexibility, and barrier behavior. These enhancements will push rHDPE applications even deeper within the packaging industry.

Intco Plastics: Your Reliable rHDPE Chips Supplier

If you need a provider for top-notch rHDPE chips, Intco Plastics should be your first choice. With their dedication to friendly solutions and a diverse selection of rHDPE items, Intco Plastics stands out as the perfect ally for sustainable packaging needs.

Commitment to sustainable solutions

Intco Plastics focuses on supporting sustainability by manufacturing and distributing rHDPE chips while maintaining high-quality standards and complying with regulations to guarantee top-notch performance and sustainability of their products.

Wide Range of rHDPE Chips Products

Intco Plastics offers a diverse range of rHDPE chip products to meet your specific packaging needs. Whether you need rHDPE for bottles, containers, films, or other applications, Intco Plastics has the right solution for you.

Conclusion

Recycling HDPE pellets presents a flexible option to the packaging sector that provides numerous advantages in terms of cost reduction and efficiency, as well as positively affecting the environment. It conserves resources and waste and aligns with the increasing demand for eco-friendly products.

FAQs

Q1: What are some of the challenges and considerations when using rHDPE pellets in packaging?

Using rHDPE pellets has advantages but also challenges. Impurities in recycled HDPE can affect mechanical qualities, so obtain specifications and quality certifications from suppliers. Color variations in recycled plastics require careful management, especially for packaging where visual appeal is crucial.

Q2: How does the use of rHDPE chips contribute to a circular economy?

rHDPE chips support the circular economy by recycling HDPE materials, reducing plastic reliance, and preserving resources. This practice lessens the environmental impact of plastic manufacturing and promotes sustainable waste transformation to decrease landfill pollution.

Q3: Why are they beneficial for use in the packaging industry?

Recycled HDPE chips benefit packaging with durability and longevity, ensuring robust transport and handling. Chemical resistance makes them suitable for diverse products. They reduce plastic waste, support a circular economy, and meet the demand for sustainable packaging.