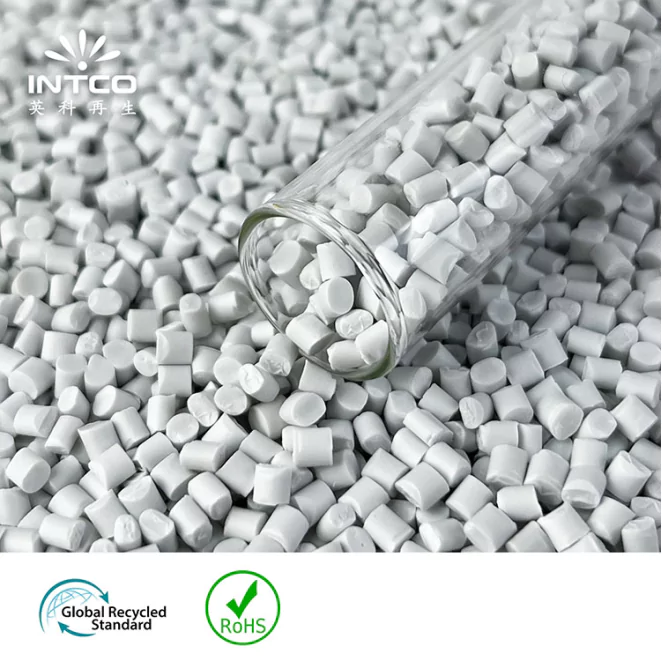

Recycled PS chips and pellets have become an integral component in the discussion of sustainability in recent years. As the world grapples with plastic waste, finding safe and efficient ways to utilize recycled materials is critical. Recycled polystyrene (rPS) products not only offer economic benefits but also serve to reduce environmental impacts.

The Role of Recycled PS Chips/Pellets in Sustainability

Recycled PS chips and pellets play a significant role in enhancing sustainability in various industries. By transforming post-consumer polystyrene waste into usable materials, companies can reduce reliance on virgin plastics, which require extensive resources for production. This recycling process not only diminishes the volume of waste sent to landfills but also conserves natural resources, thereby promoting a circular economy. As more industries adopt recycled PS chips and pellets, there emerges an opportunity to foster eco-friendly practices while contributing to a sustainable future.

Environmental Benefits

The environmental benefits of using recycled PS chips and pellets cannot be overstated. Recycling polystyrene reduces the demand for new, virgin materials, consequently decreasing the energy consumption and pollution associated with plastic production. By utilizing recycled materials, companies can lessen their carbon footprint and foster a healthier environment. Moreover, the effective management of plastic waste through recycling initiatives mitigates the adverse effects of plastics on ecosystems and wildlife, signaling a step towards more responsible resource management in industry practices.

Reduction of Greenhouse Gas Emissions

The reduction of greenhouse gas emissions is a critical factor in the push towards recycling PS chips and pellets. The production of virgin polystyrene contributes significantly to greenhouse gas emissions, primarily through the energy-intensive processes involved. Utilizing recycled PS can significantly lower these emissions, as the production process for recycled materials is required to be less energy-consuming. Furthermore, recycling polystyrene contributes to a reduced overall demand for fossil fuels, which are the primary sources for plastic production, further aiding in climate change mitigation efforts.

Regulatory Guidelines for Safety Standards

Understanding the regulatory guidelines surrounding the safety of recycled PS chips and pellets is crucial for industry stakeholders. Various national and regional authorities have established safety standards to govern the use of recycled materials to protect public health and the environment. These regulations ensure that recycled products meet safety benchmarks and that consumers can confidently utilize these materials without concern for unintended hazards.

Certifications from Regulatory Authorities

Certifications from regulatory authorities serve as vital components to ensure the safety of recycled PS chips and pellets. An essential regulatory body in the United States, the Food and Drug Administration (FDA), plays a critical role in assessing the food contact safety of recycled materials. The FDA evaluates and approves recycling technologies and processes, ensuring that the resultant recycled products are safe for consumer use. Through their stringent guidelines, the FDA helps to reinforce the safety of recycled PS chips and pellets in various applications.

EFSA Approval

Similarly, the European Food Safety Authority (EFSA) plays a crucial role in governing the safety of recycled materials in Europe. EFSA evaluates the safety of recycled plastics used in food contact applications and provides scientific assessments to guide regulatory decisions. The approval from EFSA not only reinforces consumer confidence but also promotes the safe usage of recycled PS chips and pellets in various sectors. By aligning with these regulatory bodies, companies demonstrate their commitment to maintaining safety standards while promoting sustainability.

Widely Applications

Recycled PS chips and pellets find applications in various industries, showcasing their versatility and utility. Their adaptability makes them suitable for numerous products and structures, highlighting the effective incorporation of recycled materials into mainstream manufacturing processes. The wide range of applications also reflects the growing recognition of the benefits of recycling in reducing environmental impacts.

Skirting Line

One notable application of recycled PS chips and pellets is in the manufacturing of skirting lines, commonly used in commercial and residential environments. Skirting lines made from recycled materials not only maintain aesthetic appeal but also contribute to sustainability initiatives. By substituting traditional materials with recycled PS, manufacturers can deliver products that align with eco-conscious practices while ensuring durability and functionality. This is particularly valuable in industries that prioritize sustainable building solutions.

Extruded Board

Extruded boards represent another prominent application for recycled PS chips and pellets. These boards are increasingly utilized in construction and insulation, offering excellent thermal insulation properties. The use of recycled materials in extruded board manufacturing allows construction companies to reduce their carbon footprint while benefiting from the structural advantages of PS. Moreover, as the demand for eco-friendly building materials grows, the application of recycled PS chips into these products positions companies favorably in a competitive market.

Frame

The packaging and framing industry also benefit from the incorporation of recycled PS chips and pellets. Frames made from recycled materials provide a sustainable option without compromising quality and strength. Moreover, they cater to the increasing consumer demand for green products. The ability to recycle post-consumer polystyrene into framing solutions helps to address the ongoing plastic waste challenge while promoting a circular economy. As sustainability becomes a greater priority, the application of recycled PS in frames illustrates the potential of harnessing recycled materials for innovative and responsible product design.

In conclusion, the safety implications of recycled PS chips and pellets necessitate ongoing evaluation and compliance with regulatory frameworks to ensure public health is protected. The role of these recycled materials in promoting sustainability contributes to a more efficient industry, but continued scrutiny is vital. By focusing on the environmental benefits, regulatory guidelines, and wide-ranging applications, we can better understand the value and safety of recycled PS chips and pellets in modern manufacturing and everyday use.

INTCO Recycling: Leading Manufacturer & Supplier of Recycled Plastic Pellets

About INTCO Recycling

INTCO Recycling stands as a recognized leader in the manufacturing and supply of recycled plastic pellets, particularly recycled polystyrene (rPS) chips. With a commitment to sustainable practices, INTCO utilizes advanced recycling techniques to transform post-consumer plastic waste into high-quality pellets. Its dedication not only enhances the lifecycle of plastics but also positions it as a key player in the global push towards environmental stewardship. INTCO’s operations are underpinned by an unwavering focus on quality, ensuring that its recycled products meet the rigorous demands of various industries.

rPS of INTCO

INTCO proudly produces a range of rPS products that cater to diverse applications. Their high-quality recycled PS chips and pellets have become essential in numerous sectors, showcasing the versatility and adaptability of recycled materials. With ongoing investments in technology and research, INTCO continues to improve its processes, delivering exceptional value while promoting sustainable practices.

R-PS-A

The R-PS-A, offered by INTCO MALAYSIA, is a highly versatile and eco-friendly alternative to traditional GPPS materials. These recycled PS pellets are derived from global EPS waste foam, ensuring a sustainable production process that not only minimizes waste but also conserves energy. Designed specifically for use in XPS extruded insulation foam board applications, INTCO’s Recycled PS Pellets can seamlessly replace GPPS materials while maintaining identical quality standards in terms of compressive strength, density, thickness, and thermal conductivity. This ensures that end products maintain their optimal performance characteristics, without compromising on sustainability.

R-HIPS-805

The R-HIPS-805 is a high-performance recycled material derived from home appliance casings, specifically from refrigerators and washing machines. It boasts a resin composition of high-impact polystyrene, which ensures exceptional durability and resilience. This material is rigorously tested according to international standards to guarantee consistent quality and performance.

The R-HIPS-805 exhibits impressive physical properties, including a tensile strength of 24 MPa and an elongation at break of 47%, indicating its ability to withstand tension and deformation. It also demonstrates a flexural strength of 36 MPa and a flexural modulus of 1650 MPa, ensuring high resistance to bending forces. The material’s impact strength of 8 KJ/m2 underscores its durability in impact situations, while its melting flow rate of 5 g/10min at 230°C/2.16 Kg indicates optimal processing conditions. Lastly, the R-HIPS-805 has a density of 1.05 g/cm³, making it lightweight yet sturdy, ideal for various applications requiring a balance of strength and weight.

End-to-end Traceability

INTCO implements comprehensive end-to-end traceability in its recycling processes, ensuring that all stages of production, from raw material sourcing to final product distribution, are monitored and documented. This approach is critical in maintaining transparency and accountability in the recycling supply chain. By establishing traceability, INTCO assures clients and consumers that its rPS products originate from responsibly managed processes, further enhancing the safety profile of the materials. This commitment to transparency also enables effective risk management, fostering trust in the use of recycled PS chips and pellets across diverse applications.

Advances in Recycling Techniques

Innovations in Mechanical Recycling

The field of mechanical recycling has witnessed significant innovations, enhancing the efficiency and safety of recycled PS chips and pellets. Advanced sorting and cleaning technologies allow for the effective separation of polystyrene waste from contaminants, ensuring that the recycled materials retain high quality. These innovations contribute to reducing the energy consumption associated with recycling processes, making them more sustainable. Furthermore, improved mechanical recycling techniques reduce the risk of introducing harmful substances into the final recycled products, reinforcing safety measures essential for public health.

Chemical Recycling Methods

Chemical recycling methods offer an alternative approach to processing polystyrene waste. By breaking down plastics into their fundamental monomers, chemical recycling enables manufacturers to create high-quality raw materials that can compete with virgin plastics. This method not only handles contaminated materials effectively but also addresses the limitations of traditional mechanical recycling techniques. The ability to convert various types of plastics into usable feedstock minimizes environmental impact and supports the circular economy. Safety regulations and adherence to strict chemical processing guidelines ensure the security and viability of these recycled materials while fostering innovation within the industry.

Future Trends and Developments

As the recycling landscape evolves, future trends and developments promise to shape the production and utilization of recycled PS chips and pellets. The increasing emphasis on sustainability and eco-friendly initiatives will drive further innovations in recycling technologies. Research and development will likely focus on enhancing the performance of recycled materials while identifying new applications across different sectors. Ultimately, the future of recycled PS chips and pellets appears promising, as advancements in technology and increased awareness pave the way for more sustainable and safe practices in recycling operations.