The world is moving from the current linear economy model toward a circular economy model (where we keep resources in use for as long as possible), turning its eye increasingly toward eliminating plastic waste. Polyethylene terephthalate, or PET, is a commonly used type of plastic. It can be found in beverage bottles or textiles. PET can be recycled using either mechanical or chemical methods. This makes it a frontrunner in the recycling race.

I. Introduction: The Growing Importance of PET Recycling in a Circular Economy

In today’s society, we are addressing the challenges posed by pollution impacts head-on. Polyethylene Terephthalate (PET) stands out as a frontrunner. PET is renowned for its adaptability and extensive use in beverage containers, packaging components, and fabric products which positions it as a player in fostering a circular economy mindset. This shift, in attention highlights the significance of waste reduction and resource conservation through prolongation of materials lifecycle. Consequently, PET recycling contributes significantly to achieving this vision.

This blog explores the two approaches to PET recycling – mechanical and chemical recycling methods – to gain insights into their procedures as well as their respective benefits and constraints to underscore the importance of selecting the most suitable recycling option.

II. Mechanical Recycling: The Preferred Solution for Sustainable PET Recycling

Recycling PET through means is widely favored due to its simplicity and cost efficiency, making it a convenient and easily scalable solution thanks to its established infrastructure.

A. The Mechanical Recycling Process

The process of recycling PET mechanically consists of clear steps that each play a role in creating high-quality recycled PET (rPET).

a. Collection and Sorting: The Foundation of High-Quality rPET

The process starts by gathering used PET materials from places after they’ve been used by consumers. The materials are carefully separated according to their colors and shapes to make sure they are clean and free from any impurities. This stage plays a role because how pure the initial materials are affects the excellence of the end recycled PET product.

b. Washing and Separation

The cleaned PET waste goes through a cleaning procedure to eliminate dirt and impurities like debris by soaking and stirring the plastic in a water and detergent mixture. Additional methods may be used to separate materials from other plastic types and non-plastic elements to guarantee a pure stream, for additional treatment purposes.

c. Extrusion: Transforming Flakes into Usable rPET Pellets

After washing and separation, the PET waste is typically shredded and ground into small flakes. These flakes are then dried to remove moisture before being fed into an extruder. The extruder melts the flakes and forms them into pellets, which are easier to handle and transport. These rPET pellets serve as the raw material for manufacturing new products.

B. Why Mechanical Recycling Remains the Dominant Solution for PET Recycling

In the PET industry mechanical recycling remains popular and effective due to factors.

1. Cost-Effectiveness

The cost-effective choice is mechanical recycling because it needs simpler equipment and skills than other recycling methods do, leading to reduced expenses in both initial investments and day-to-day operations for businesses and city administrations alike, making it a popular option across various sectors.

2. Energy Efficiency

The process of recycling is quite efficient in terms of energy usage. It requires less energy than the production of virgin PET or even chemical recycling processes. This is not only in line with sustainability objectives but also helps reduce the environmental impact linked to PET recycling.

III. Chemical Recycling: An Emerging Technology with Challenges

An alternative method to recycling PET is chemical recycling, where polymer chains are broken down into their units (monomers) for making new PET products. This technique shows potential to overcome some drawbacks of mechanical recycling but encounters notable obstacles as well.

A. The Chemical Recycling Process: Depolymerization and Repolymerization

Chemical recycling is about depolymerization. A method of splitting PET into its basic units is known as purified terephthalic acid (PTA) and monoethylene glycol (MEG). Different chemical reactions(glycolysis or methanolysis) can be employed within catalysts and reaction settings for effective achieve. Once the monomers are obtained through this process, they can be reprocessed to produce high-quality virgin PET material.

B. Limitations of Chemical Recycling:

While chemical recycling holds promise for the future.

a. High Cost with High Complexity

Processing chemicals through recycling involves using machinery and skilled knowledge. Maintaining strict control over the more intricate and expensive reaction environment than mechanical recycling methods. The increased expenses associated with chemical recycling may hinder its adoption—especially in areas with scarce resources or underdeveloped infrastructure.

b. Potential Environmental Impact

Chemicals and catalysts in chemical recycling can impact the environment if not handled correctly. The energy usage varies based on the technology employed. Thus, it’s crucial to assess the effects of chemical recycling, for sustainability purposes.

IV. Mechanical Recycling vs. Chemical Recycling: A Comparison Table

| Feature | Mechanical Recycling | Chemical Recycling |

| Process | Shredding, washing, melting, and extrusion | Depolymerization and repolymerization |

| Cost | Lower | Higher |

| Energy Consumption | Lower | Higher |

| Material Quality | Can degrade with multiple cycles | Can produce virgin-quality PET |

| Environmental Impact | Generally lower | Can be higher depending on chemicals and energy use |

| Infrastructure | Well-established | Still developing |

V. INTCO: A Global Leader in Mechanical PET Recycling

INTCO Recycling is a shining example of a company dedicated to advancing the circular economy in plastics, particularly through its expertise in mechanical PET recycling.

A. INTCO’s Commitment to a Circular Economy in Plastics

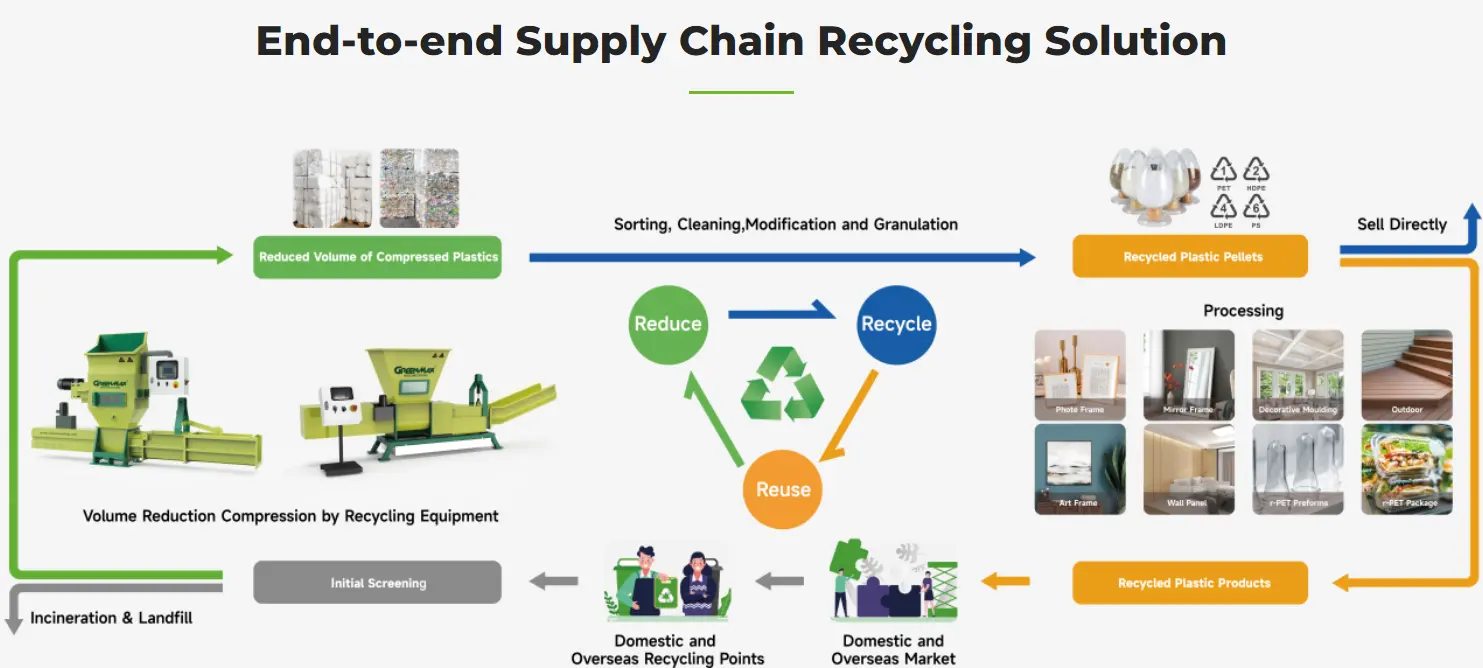

INTCO has been promoting the reuse of plastics by turning recycled plastics into trendy consumer goods. Thus they developed a comprehensive supply chain that showcases the effectiveness of a circular economy approach. Their dedication to sustainability goes beyond recycling and includes ethical sourcing practices and reducing environmental harm in all aspects of their business.

B. INTCO’s Production Base in Malaysia: Promoting Sustainable Practices

INTCO’s global reach which includes operations in Malaysia, focused on promoting sustainable practices through their production facilities serving as a center for responsible recycling efforts on a global level.

C. INTCO’s Expertise: Delivering High-Quality rPET Consistently

INTCO’s expertise in recycling by consistently providing top-notch rPET products that meet the strict requirements of different industries, thanks to their commitment to quality control and process improvement to ensure the safety and reliability of goods made from recycled materials.

VI. Conclusion: Join INTCO for a Sustainable Future

When aiming for a tomorrow, the focus is on PET recycling as a key player. Mechanical recycling stands out as the leading choice, acknowledged for its cost efficiency, energy conservation efforts, and existing operational framework. Although chemical recycling shows potential, challenges persist in terms of costs and environmental repercussions.

INTCO Recycling’s commitment to embracing an economy for plastics and their expertise in mechanical recycling showcases the significant benefits of responsible recycling on both the environment and the economy. Opt for recycled materials and backing initiatives such as those undertaken by INTCO to aid in creating a greener and more enduring future for upcoming generations.