Understanding Recycled PET

What is Recycled PET?

Polyethylene Terephthalate (PET) is a prevalent thermoplastic polymer extensively utilized in packaging, with particular emphasis on beverage bottles. Recycled PET pertains to previously used PET products that undergo collection, sorting, and reprocessing for future applications. This recycling process significantly diminishes the need for virgin PET production while concurrently mitigating plastic waste’s environmental footprint. The adoption of recycled PET is experiencing considerable growth as businesses and consumers increasingly prioritize sustainability and environmental stewardship.

The Process of Recycling PET

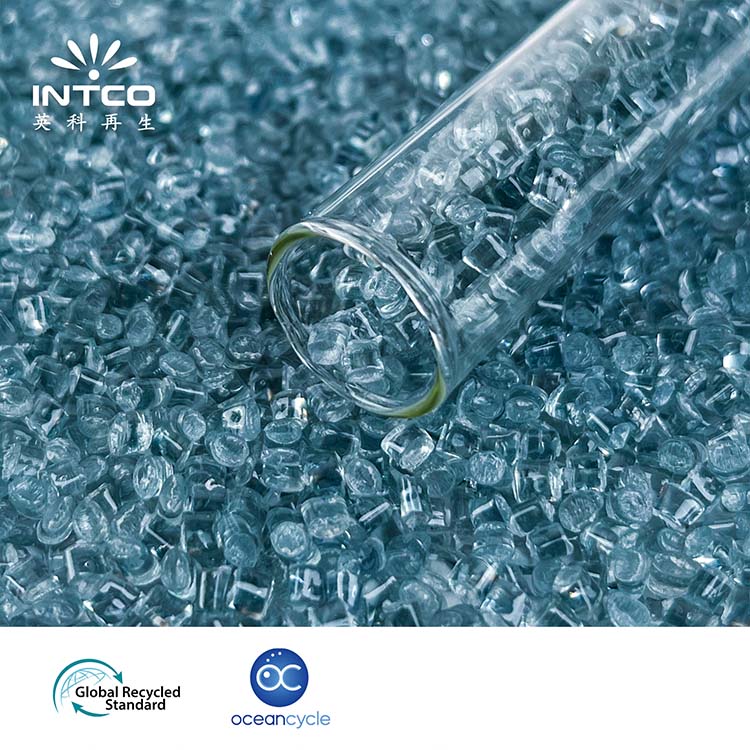

The recycling of PET involves several stages. Initially, PET products are collected and transported to recycling facilities. Here, they undergo sorting to separate PET from other materials. The sorted PET is then washed to remove impurities and contaminants. This clean PET is shredded into flakes, which are further processed into pellets. These pellets can be melted and molded into new products. The recycling process conserves energy and resources, promoting sustainable practices within industries that rely heavily on PET.

Environmental Impacts of Recycled PET

Carbon Footprint Reduction

Using recycled PET significantly reduces the carbon footprint associated with plastic production. The energy consumed during the recycling process is considerably lower compared to producing virgin PET. This reduction in energy use leads to fewer greenhouse gas emissions, helping to mitigate climate change. Studies show that carbon emissions can be reduced by up to 60% when using recycled PET instead of virgin plastic, making it a crucial component of eco-friendly practices.

Energy Consumption in Production

The production of recycled PET requires less energy than creating new PET from raw materials. Energy savings stem from the fact that the recycling process bypasses several energy-intensive steps involved in petrochemical extraction and polymerization. These energy savings translate into decreased fossil fuel use, contributing to a lower overall environmental impact. Thus, the recycling of PET plays a critical role in cutting down the energy footprint of plastic manufacturing.

Waste Reduction and Landfill Diversion

Recycled PET contributes significantly to waste reduction by redirecting plastic waste away from landfills. Through recycling PET, used bottles and containers are reprocessed, preventing them from exacerbating the issue of plastic pollution. This process aids in preserving landfill space and mitigates the environmental release of microplastics that can be detrimental to wildlife and ecosystems. Additionally, advocating for the use of recycled PET promotes enhanced global waste management practices.

Benefits of Using Recycled PET Products

Sustainable Resource Management

The use of recycled PET supports sustainable resource management by minimizing the reliance on non-renewable resources. Recycling PET closes the loop in the plastic lifecycle, making it part of a circular economy where materials are continuously reused. This not only conserves raw materials but also promotes the sustainable use of resources in various industries, contributing to long-term environmental health.

Applications in Everyday Products

Packaging Solutions

Recycled PET is widely used in packaging solutions such as bottles, containers, and trays. Beverage companies, in particular, are adopting recycled PET to meet consumer demands for sustainable packaging. Using recycled PET in packaging reduces the environmental burden while still providing the safety and durability required for food and beverage products.

Textile Industry Use

The textile industry is another significant user of recycled PET. Companies turn plastic bottles into fibers that are spun into clothing, reducing the need for virgin polyester. Brands like Patagonia leverage recycled PET to create sustainable fashion lines, demonstrating that recycling can yield high-quality materials suitable for various applications. This practice not only conserves resources but also appeals to eco-conscious consumers.

Automotive Components

Recycled PET is also making its way into the automotive industry. It’s being used to produce carpets, seat fabrics, and various interior vehicle components. Incorporating recycled PET in automotive manufacturing not only helps in reducing vehicle weight, thereby enhancing fuel efficiency, but also aligns with the industry’s sustainability goals. This use case demonstrates the versatility and potential of recycled PET across different sectors.

INTCO Recycling is a high-tech manufacturer specializing in resource recycling. They have created a full supply chain with recirculated plastics, including their recycled PET (rPET) products. rPET is produced by collecting post-consumer PET bottles and processing them into high-quality recycled PET pellets. These pellets are widely used in various applications such as beverage bottles, food packaging, fibers, textiles, and straps.

INTCO’s rPET pellets are certified with FDA, EFSA, and GRS, ensuring their compliance with food safety and environmental standards. The company is committed to sustainable development and environmental responsibility. Through their recycling efforts, they have the capacity to recycle 50,000 tons of PET bottles annually, saving 450,000 tons of crude oil, reducing carbon emissions, and preserving millions of trees.

Comparing Recycled PET with Other Materials

Versus Virgin PET

Compared to virgin PET, recycled PET consumes less energy and resources, thus offering notable environmental benefits. While virgin PET production involves the extraction and processing of fossil fuels, recycled PET utilizes existing plastic waste, making it a more sustainable option. Moreover, using recycled PET reduces greenhouse gas emissions and decreases landfill waste, attributes that make it favorable over virgin PET.

Versus Biodegradable Materials

When compared to biodegradable materials, recycled PET offers advantages in terms of lifecycle and durability. While biodegradable plastics break down more quickly under certain conditions, they may not always be suitable for all applications. Recycled PET provides a more robust solution for products that require long-term durability and resilience. Additionally, recycling PET upholds resource efficiency compared to the often higher energy requirements of producing biodegradable plastics.

Versus Glass and Metal

Recycled PET also stands out when compared to materials like glass and metal. Glass and metal recycling can be more energy-intensive due to the high temperatures needed for processing. In contrast, recycled PET can be processed at relatively lower temperatures, conserving energy and reducing carbon emissions. Furthermore, recycled PET is lighter, which can decrease transportation costs and associated emissions, making it a practical and eco-friendly alternative.

By grasping the advantages and evaluating recycled PET against alternative materials, it becomes evident that recycled PET stands out as an outstanding option for eco-friendly consumers aiming to contribute positively to the environment.

Consumer Choices and Sustainability

How to Identify Recycled PET Products

Recognizing items made from recycled PET is crucial for eco-conscious shoppers. These products often feature labels with the recycling symbol and the letters “PET” or “rPET.” Consumers can also search for certifications like the Global Recycled Standard (GRS) or logos from reputable environmental organizations. These indicators confirm that the products meet certain standards for recycled content and sustainability practices.

Ethical Consumerism: Making Informed Choices

Ethical consumerism involves making informed choices that prioritize sustainability and environmental responsibility. Consumers can support the use of recycled PET by choosing products that clearly state their recycled content and by favoring brands that demonstrate a commitment to sustainability. Researching brands, understanding their production practices, and selecting items with minimal packaging are ways to contribute to ethical consumerism. These choices help drive market demand for recycled PET products and encourage more companies to adopt eco-friendly practices.

The Role of Certifications and Standards

Certifications and standards play a pivotal role in promoting the use of recycled PET. Standards such as the ISO 14021 for environmental labels and declarations ensure transparency and credibility in the labeling of recycled content. Certifications like the Global Recycled Standard (GRS) provide verification of recycled materials, helping consumers trust the origins and sustainability of their purchases. By adhering to these standards, manufacturers can bolster consumer confidence and support the broader adoption of recycled PET in various industries.

Future Trends in Recycled PET Usage

Innovations in Recycling Technology

Emerging technologies are set to revolutionize the recycling of PET. Advanced chemical recycling methods, such as PET depolymerization, break down plastic waste into its basic monomers, allowing for high-quality recycling without significant loss of properties. Innovations like the proprietary Magnetic Fluids process by Ioniqa Technologies enhance the efficiency and cost-effectiveness of recycling, opening new possibilities for the application of recycled PET. These technological advancements promise to address existing limitations and expand the usability of recycled PET well into the future.

Legislative Support and Policy Changes

Government policies and legislative support play a crucial role in promoting the adoption of recycled PET. Laws mandating a minimum recycled content in packaging or offering incentives for recycling initiatives can significantly influence industry practices. For example, bans on single-use plastics and mandates for recyclable packaging materials drive the increased use of recycled PET. By enacting supportive policies and providing financial incentives, governments can facilitate the scaling of recycling processes and boost market demand for recycled PET.

Increasing Corporate Commitments to Sustainability

Corporate commitments to sustainability are enhancing the future landscape for recycled PET. Major companies, from beverage giants like Coca-Cola and PepsiCo to fashion brands like Patagonia and Gucci, are incorporating recycled PET into their product lines and packaging. These commitments often go hand-in-hand with substantial investments in recycling infrastructure and consumer education programs. As more corporations prioritize environmental stewardship, the availability and consumer acceptance of recycled PET products will likely expand dramatically.

By understanding and addressing the challenges and leveraging advancements in technology, policy, and corporate commitment, the future of recycled PET looks promising for eco-conscious consumers. With continued support and innovation, recycled PET can play a significant role in driving sustainability and curbing environmental impact.

Driven by proactive innovation, INTCO aims to become a global leader in resource recycling. They continue to advance their plastic recycling technologies and expand their product offerings to include other types of plastics. With their dedication to sustainability and circular economy principles, INTCO Recycling contributes to a greener and more environmentally conscious future.