Recognizing recycled polystyrene (rPS) items is important for consumers as it promotes sustainability and improves the recycling process in business settings. Choosing rPS means that you are playing a part in reducing waste and supporting companies that value eco-friendly materials. Acknowledging these products increases the demand for recycled materials and encourages businesses to adopt sustainable approaches. Furthermore, as industries move towards more sustainable economies, recognizing rPS can help you make purchasing decisions that align with your beliefs.

Benefits of Using Recycled PS

Recycling polystyrene (PS) offers many benefits. It helps preserve resources, save energy, and reduce greenhouse gas emissions compared to making polystyrene from scratch. Turning recycled PS into products helps reduce the reliance on oil-based materials and promotes a smaller carbon footprint overall. Additionally, incorporating recycled PS chips or pellets in production contributes to building an economy where materials are reprocessed, reused, and repurposed. This approach not only strengthens economies but also improves the sustainability of products in various industries.

Environmental Impact of Polystyrene Recycling

Recycling polystyrene helps reduce the impact of waste on the environment. When you recycle PS materials, they are diverted from landfills, where they take centuries to break down. Additionally, recycling saves energy, as it typically takes more energy to produce plastic from raw materials. As environmental concerns grow, choosing recycled polystyrene items allows individuals to contribute to a greener future and encourages businesses to adopt eco-friendly practices.

How to Recognize Recycled PS (rPS) Products?

It’s important to pay attention to specific cues that indicate the original origin and properties of recycled products. Many companies provide information about their items to help buyers confirm the authenticity and eco-friendly benefits of recycled plastic (rPS) products. Familiarizing yourself with these clues ensures that the choices you make actively support recycling initiatives and environmental conservation efforts.

Common Features of rPS Products

Recycled polystyrene products often have unique characteristics that set them apart from brand-new versions. For example, rPS items may display certifications such as the Global Recycled Standard (GRS) or other eco-friendly labels, indicating environmentally sustainable sourcing and manufacturing methods. Additionally, these products may have a different texture or color compared to new polystyrene products, making them more noticeable and distinctive. Paying attention to these details can help you make informed decisions when shopping for eco-friendly products.

Visual Indicators of Recycled PS

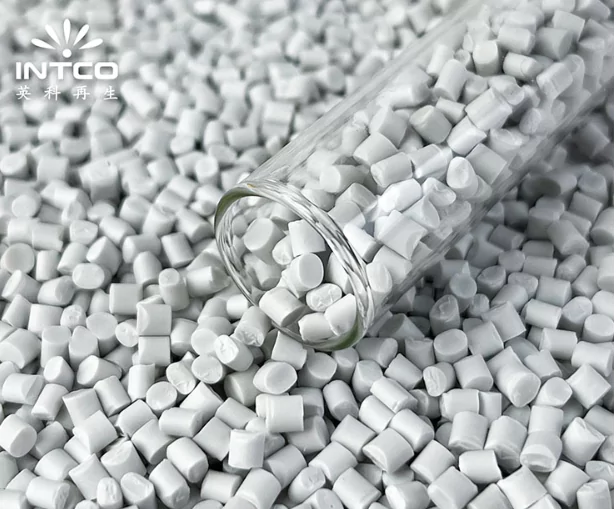

Sometimes, you can identify recycled polystyrene (rPS) products by examining the colors and markings on the packaging or the product itself. Manufacturers often use symbols or codes like the recycling triangle with the number six to indicate such products. Intcoplastic provides information on their recycled PS pellets to demonstrate their origin and quality standards. By familiarizing yourself with these cues, you can readily identify recycled PS items in your daily life.

Differences Between Virgin PS and Recycled PS Chips/Pellets

The main differences between virgin PS and recycled PS chips or pellets are found in how they’re made and where their materials come from. Virgin PS comes from oil, while rPS comes from waste materials like EPS (Expanded Polystyrene) and used consumer products. Additionally, recycled PS chips are often blended with other recycled materials, which affects their characteristics and uses. Understanding these distinctions can help you make informed decisions about the products you choose to use, supporting sustainability objectives.

Using Intcoplastic’s recycled PS pellets sourced from EPS waste foam worldwide, you can play a role in conservation while benefiting from strong insulation options for different uses. The item is crafted to mirror the traits of materials, guaranteeing energy efficiency and effectiveness.

How Do Intcoplastic Products Incorporate Recycled PS?

Recycled polystyrene (rPS) has become a component, in the product lineup of companies such as Intcoplastic in years. Intcoplastic sources EPS waste foam from around the world to create recycled PS pellets that serve as an alternative to virgin PS. This strategic move does not reduce dependency on petroleum-based resources. Also encourages eco-friendly practices within the plastics sector. By incorporating rPS into their products these companies demonstrate how they can align their business practices with objectives while ensuring quality and performance, in their offerings.

Intcoplastic’s Role in Promoting Sustainability

Intcoplastic is dedicated to promoting sustainability by incorporating materials into its products. They reduce the volume of waste disposed in landfills by concentrating on gathering and reusing EPS waste material. This supports the concept of an economy. Their dedication is apparent, through their certifications such as GRS and REACH. These certifications ensure sourcing and extensive environmental regulations. Through these efforts, Intcoplastic encourages a mindset, among businesses inspiring them to implement comparable strategies which in turn contributes towards a more environmentally friendly planet.

Product Range Offered by Intcoplastic Featuring rPS

Intcoplastic offers a variety of products that make use of recycled PS pellets in applications such, as extruded insulation foam boards. Their product range includes items with qualities to virgin PS maintaining high standards without compromising on quality. Choosing these recycled PS-based products does not save energy during production. Also meets strict quality requirements in different uses. By selecting these options customers and producers are supporting efforts to reduce environmental impact and fulfill the increasing need, for sustainable solutions.

Real-World Tips for Consumers to Identify rPS Products

Knowing how to spot recycled polystyrene (rPS) products can help you make choices when shopping and promote friendly practices in the long run. Skills such, as understanding product labels and certifications and recognizing cues can assist you in identifying recycled PS items as you go about your routine.

Checking Labels and Packaging Information

When you’re checking out products at the store or online shopping sites… It’s important to pay attention to the labels and packaging details! Make sure to look for those symbols that show if something is made from materials – like the recycling triangle, with numbers attached to it. Some brands like Intcoplastic go the mile. Tell you how much of their products are made from recycled materials right there on the packaging! And don’t forget about certifications, like GRS – they vouch for the fact that these products are indeed recycling champs! It’s nice to know your choices are eco-friendly and legit.

Evaluating Product Certifications Related to Recycling

Product certifications are valuable signals of a product’s sustainability credentials and environmental impact assessment tools can help validate these credentials as sources of information, for consumers to consider when making purchasing decisions. International certifications like GRS, REACH, and ROHS play a role in guaranteeing transparency and accountability in the sourcing and processing of recycled materials. Choosing products with these certifications can give consumers confidence in the responsibility of their choices. Intcoplastics’ commitment, to meeting standards, showcases their dedication to delivering top-quality recycled PS products that contribute positively to protecting the environment.

By using these suggestions and exploring offerings from brands such, as Intcoplastic; you can effectively maneuver through the realm of recycled PS by making decisions that promote increased sustainability, within the plastic sector.

Common Misconceptions about Recycled PS

Myths vs. Facts: Durability of rPS

Lots of people have ideas, about how recycled PS (known as rPS) really can be compared to new plastic materials like polystyrene that haven’t been used before. There’s this myth going around that rPS isn’t as tough or sturdy as its counterpart. The truth? Made items crafted from PS by companies like Intcoplastic are built to be just as durable (if not more so) than regular polystyrene products out there. The quality of products made from rPS has come a long way over the years. Now they perform just as well in various uses, like insulation and packaging when compared to traditional plastics.

Times rPS can endure conditions just as effectively as new PS can do so too. By following testing procedures and complying with industry norms manufacturers frequently demonstrate the durability of rPS which helps to address concerns, about its lasting power and efficiency. Acknowledging the robustness of rPS items empowers consumers to make decisions that promote eco behaviors without sacrificing quality.

Addressing Concerns About Quality and Safety

Worries regarding the reliability and safety of recycled materials can occasionally dissuade customers from selecting rPS items. There are concerns that recycled materials may contain impurities or involve standards, in their creation process. Nonetheless respected companies such, as employ processing methods to guarantee that recycled PS chips and pellets adhere to rigorous safety standards. These goods undergo cleaning, sorting, and quality control processes effectively addressing any safety worries.

Additionally, the certifications, like GRS and ROHS serve to confirm the safety and eco-friendliness of recycled PS items so and show that they comply with stringent standards when it comes to product safety and sustainability guidelines are followed closely too.

Intcoplastic: Trusted Brand

Intcoplastic is a well-known figure in the plastics industry. The company focuses on creating high-quality recycled PS (polystyrene) items by obtaining EPS (expanded polystyrene) waste foam from various global providers. They produce recycled PS pellets that serve as substitutes for materials, meeting high industry standards while ensuring performance quality through thorough testing processes.

Intcoplastic places a strong emphasis on sustainability. They not only meet the increasing demand for eco-friendly options but also take proactive steps to visibly reduce plastic waste. The company’s commitment to upholding standards is evident through its certifications, such as GRS and REACH, which instill trust among consumers regarding the recycled PS products they offer.

In a time where retailers are actively seeking environmentally friendly options for their customers, partnering with Intcoplastic not only allows businesses to embrace ecological values but also ensures that consumers receive products of exceptional quality.

With its forward-thinking methods and dedication to protecting the environment, Intcoplastic has solidified its reputation as a respected name in both consumer and industry circles. Opting for Intcoplastic’s recycled PS items represents a move towards creating a greener tomorrow, actively contributing to the economy while enjoying long-lasting materials that offer top-notch performance.