Recycled PET (rPET) serves as a potent solution to the pervasive plastic waste issue, transforming discarded materials into a sustainable resource. This process not only mitigates environmental concerns but also offers numerous economic benefits. As industries and consumers increasingly focus on sustainability, understanding the multifaceted advantages of using recycled PET is crucial.

The Advantages of Using Recycled PET (rPET)

Economic Benefits

Recycled PET presents an array of economic benefits that are important for both manufacturers and consumers. The utilization of rPET reduces reliance on virgin materials, which can be costly due to fluctuations in oil prices. This cost-efficiency in production allows businesses to maintain competitive pricing while actively participating in environmental conservation. Furthermore, as awareness of sustainability grows, products made from rPET can enhance brand reputation and consumer loyalty, leading to potential increases in sales and market share.

Cost-Efficiency in Production

The manufacturing process of products using rPET is generally more cost-effective than those created from virgin plastic. The costs associated with extracting and processing raw materials tend to be higher than sourcing recycled materials. By integrating rPET into production lines, manufacturers can allocate resources more efficiently, potentially lowering overall production costs. Additionally, advancements in recycling technology have improved the quality and consistency of rPET, ensuring that it meets the rigorous standards required across various applications.

Energy Savings

An often-overlooked benefit of using recycled PET is the significant energy savings achieved during production. The recycling process consumes considerably less energy compared to the production of virgin PET, primarily due to the reduced need for raw material extraction and processing. By lowering energy consumption, industries contribute to a decrease in greenhouse gas emissions, aligning with global sustainability goals. The switch to rPET not only decreases energy usage but also provides businesses with an opportunity to enhance their environmental stewardship, attracting eco-conscious consumers.

Use in Various Industries

Recycled PET has carved a niche for itself in a variety of industries, owing to its versatility. From textile fibers to packaging materials, rPET has proven itself as a reliable alternative to virgin plastics. In the fashion industry, for example, brands are increasingly producing garments from rPET fibers, which not only helps mitigate waste but also speaks to the ethos of sustainability among consumers. In packaging, the application of rPET in bottles and containers not only reduces reliance on new plastics but also enhances the recyclability of products. The widespread engagement across industries showcases the adaptability and potential of rPET to replace traditional materials.

The PET Recycling Process

The journey of transforming PET waste into valuable recycled PET begins with the collection and sorting of plastic materials. Efficient collection systems are essential to ensure a steady supply of materials for recycling facilities. The sorting process involves categorizing waste based on its polymer type, as well as separating rPET from other contaminants, which is vital for maintaining the quality of the final product.

Collection and Sorting

The initial phase of the PET recycling process is crucial for establishing the quality of the recycled product. Collection systems vary from curbside recycling bins to drop-off centers, to encourage consumer participation. Once collected, the materials undergo sorting, either manually or through automated systems. This meticulous approach helps to remove contaminants while grouping similar types of PET, setting the stage for effective recycling.

Cleaning and Shredding

After sorting, the next crucial step involves cleaning and shredding the collected PET. This process is paramount in ensuring that any labels or residual materials are removed, as they can compromise the quality of rPET. Label removal, in particular, requires specialized methods that range from water washing to the use of chemicals, depending on the type of materials adhered to the PET. The cleaning process must be thorough to meet industry standards, ensuring that the shredded material is pure and ready for further processing.

Label Removal

Labels are often made from different materials compared to the PET container, necessitating significant attention during the recycling process. Efficient label removal techniques are essential to prevent contamination and maintain the integrity of the rPET. Each label type may require distinct methods of removal, and as technology advances, more efficient solutions are being developed. Addressing this challenge enhances the overall quality of recycled materials and supports manufacturers in achieving their sustainability goals.

Further Processing and Pelletizing

The final stages of the recycling process involve further processing and pelletizing the cleaned and shredded material. This phase transforms the recycled PET into small pellets, which can easily be transported and used in new manufacturing processes. Through techniques such as extrusion and granulation, the clean PET is melted down and formed into uniform pellets, ready for use in various applications. The pelletized rPET is a valuable resource for companies, providing them with the necessary raw materials to produce new products while promoting a circular economy.

The recycling of PET into rPET offers compelling advantages across economic, environmental, and industrial dimensions. By embracing recycled materials, industries can contribute significantly to reducing plastic waste while enjoying the benefits of cost-efficiency and energy savings. Understanding the PET recycling process is essential for stakeholders committed to enhancing sustainability efforts and fostering a more resource-efficient economy. As the demand for sustainable practices grows, the significance of rPET as a transformative resource will continue to expand, opening new avenues for innovation and environmental responsibility.

INTCO Recycling: High-tech Recycled Resource Manufacturer

INTCO Recycling stands as a pioneer in the field of recycled PET (rPET) manufacturing, utilizing high-tech processes to convert plastic waste into valuable resources. Leveraging advanced technologies, the company transforms discarded materials into high-quality recycled products that meet stringent industry standards. This innovative approach not only addresses pressing environmental challenges but also supports a circular economy by reintroducing materials back into the production cycle. As a leader in the industry, INTCO Recycling demonstrates the significant potential of rPET as an alternative to virgin plastic, underscoring the need for sustainable manufacturing practices.

Advanced Recycling Technologies

The advancement of recycling technologies is crucial in determining the efficiency and effectiveness of plastic waste processing. INTCO Recycling employs state-of-the-art machinery capable of automated sorting, washing, and pelletizing processes. Equipped with sophisticated sensors and AI diagnostics, these systems significantly enhance the purity and quality of the rPET produced, providing manufacturers with a reliable raw material option. Moreover, ongoing investment in research and development ensures that the company remains at the forefront of technological innovation within the recycling sector, ultimately driving improvements in waste management practices.

Contribution to Global Sustainability Efforts

INTCO Recycling’s commitment to environmental sustainability transcends mere compliance with regulatory standards; it embodies a holistic approach to waste management that emphasizes resource recovery. By converting waste into rPET, the company effectively mitigates the detrimental impact of plastic pollution on ecosystems and communities. Additionally, by promoting the use of recycled materials within various industries, INTCO Recycling aids in reducing the carbon footprint associated with plastic production. As stakeholders from across the globe increasingly demand sustainable solutions, companies like INTCO Recycling demonstrate how rPET can play a pivotal role in achieving collective environmental goals.

rPET Products Introduction

The introduction of rPET products manufactured by INTCO Recycling highlights the versatility and utility of recycled materials across various sectors. These products are designed to meet the diverse requirements of consumers and industries alike, proving that sustainability does not come at the expense of quality or performance.

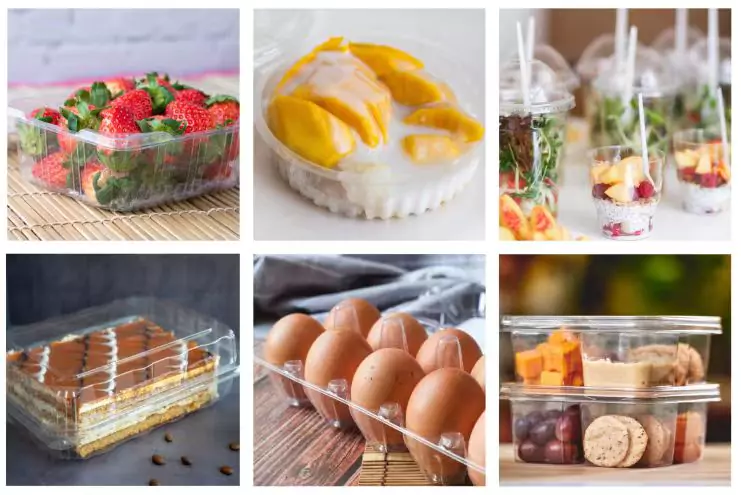

Thermoforming Products

Thermoforming products are versatile and widely used in various industries, particularly in the food packaging sector. These products, including deli containers, clamshells, bakery containers, egg trays, fruit & vegetable clamshells, and cups & lids, offer a convenient and practical solution for storing and transporting food items. The key advantage of these products lies in their high degree of customization. Customers can have their functions, sizes, and colors tailored to their specific needs, ensuring that the final product perfectly meets their requirements.

Furthermore, these thermoforming products can be made with varying levels of rPET content, ranging from 30% to 100% recycled PET. This not only helps reduce waste and promote environmental sustainability but also allows for cost savings. The process technology and products themselves have undergone rigorous testing and have been certified by multiple reputable organizations, such as Recyclass, GRS, FSSC22000, EFSA, and FDA. These certifications serve as a testament to the quality, safety, and reliability of these thermoforming products, making them a trusted choice for food packaging applications.

R-PET-WTK-01

The R-PET-WTK-01 product utilizes clean bottles as its base material, featuring a resin component of polyethylene terephthalate (PET). This product boasts several advantages, including a consistent and uniform white color, which provides an aesthetically pleasing appearance. Additionally, it is known for its high purity, achieved through the use of a 600-mesh filter during the manufacturing process. This ensures that the product is free from impurities, making it a reliable and safe choice for various applications.

Future Trends in PET Recycling

The landscape of PET recycling is evolving rapidly, driven by advancements in technology and shifting consumer preferences towards sustainable materials. A careful examination of future trends reveals significant potential for innovation in the recycling sector, particularly in enhancing the quality and usability of rPET products. As industries increasingly prioritize sustainability, the demand for high-standard recycled materials will influence production practices and material-sourcing decisions across sectors.

Innovations in Recycling Technologies

Continued innovations in recycling technologies hold the promise of revolutionizing the PET recycling process. Recent advancements in mechanical and chemical recycling techniques allow for more efficient breakdown of plastics, enabling the recovery of materials that were previously deemed non-recyclable. For example, innovations like enzymatic recycling and enhanced sorting capabilities contribute to higher purity levels in the final rPET products. Furthermore, the development of closed-loop recycling systems—where products are designed specifically for reusability—emphasizes the importance of sustainable design in creating a circular economy.

Growing Demand for Sustainable Materials

The surge in consumer awareness regarding climate change and environmental impacts has resulted in an escalating demand for sustainable materials across various industries. Companies are increasingly motivated to adopt eco-friendly practices, with many setting ambitious sustainability goals aimed at reducing their reliance on virgin plastics. This market shift creates a unique opportunity for manufactured rPET products like those from INTCO Recycling to play a crucial role in fulfilling these demands. Brands that embrace the use of rPET in their supply chain not only bolster their sustainability initiatives but also appeal to environmentally-conscious consumers looking for responsible purchasing options.

The future of recycled PET and its applications lies in the industry’s ability to adapt and innovate continuously. As technologies advance and demand for sustainable materials grows, rPET stands poised to transform from a waste product into a cornerstone of critical manufacturing practices, paving the way for a more sustainable and resource-efficient future.