This blog article explores how recycled polystyrene (known as rPS) helps reduce carbon footprints by discussing its advantages and various recycling methods while also showcasing its range of uses and emphasizing its important role in promoting a sustainable circular economy.

Definition of Carbon Footprint

It’s crucial to grasp the terms to truly understand how rPS affects the environment.

The carbon footprint is a method of measuring the greenhouse gas emissions from human activity in units of carbon dioxide equivalents. Like those from fossil fuel burning and activities like deforestation that cause climate change levels on the globe and the quantity of emissions discharged into the air by a person or an institution like an organization or a nation has a role to play in reducing this impact to combat climate change effects and preserve the planet for future generations.

Explain the importance of reducing carbon footprints to mitigate climate change.

It’s essential to reduce our carbon footprint for a variety of reasons.

Reducing greenhouse gas emissions can help to slow down climate change by addressing increasing temperatures and extreme weather events while also tackling rising sea levels.

Preserving ecosystems is crucial as it helps maintain the homes of plants and animals while safeguarding their survival and biodiversity.

Let’s work together to create a future by reducing our impact on the environment and safeguarding a healthier planet for the next generations to come.

Decoding Polystyrene and Its Environmental Impact

Polystyrene is a used plastic that poses environmental issues because it does not break down naturally in the environment.

What is Polystyrene (PS)?

Polystyrene is a plastic material that is lightweight and adaptable and finds applications in various industries due to its excellent insulation properties thanks to its low thermal conductivity feature. It is available in two types. Expanded polystyrene (EPS) is a lightweight foam produced by expanding tiny beads using steam; and non-expanded polystyrene that is dense and rigid in form.

The environmental challenges of using Polystyrene.

Despite its undeniable usefulness, polystyrene causes significant environmental problems:

Polystyrene poses a challenge due to its resistance to natural breakdown processes which contribute to plastic waste and buildup in landfills.

Impact on Wildlife; Harm is caused to animals as they frequently confuse polystyrene with food leading to consequences.The breakdown of results in the creation of harmful microplastics that impact marine life and possibly humans as well.

Waste Production Issue; An estimated 12 billion kilograms of polystyrene are generated globally annually resulting in waste generation.

The rPS Advantage: How Recycled Polystyrene Reduces Carbon Footprint

Using recycled polystyrene presents an eco option as it helps lower energy usage and greenhouse gas emissions while also decreasing the need for new materials.

Energy Conservation in rPS Production

When it comes to making polystyrene it uses a lot less energy compared to making new plastic from scratch. Recycled plastic can be melted down. Molded again without needing too much refining or purifying. This whole energy-saving process leads to a carbon footprint in the end.

Reduced Greenhouse Gas Emissions

Using plastics helps lower greenhouse gas emissions by reducing the amount of waste sent to landfills and decreasing the demand for new resources to make products, which in turn reduces emissions linked to plastic manufacturing and transportation.

Decreased Demand for Virgin Materials

By using recycled polystyrene of relying on oil and other fossil fuels. Which are major contributors to greenhouse gas emissions. The need for extracting these resources is lowered. This approach not only helps in addressing climate change but also encourages sustainable practices.

rPS Contributes to a Circular Economy

Polystyrene recycling contributes to the economy by reusing materials instead of throwing them away. This method helps save resources cuts down landfill usage and lessens the footprint overall.

rPS Recycling: Processes and Technologies

Advancements in recycling technologies play a role in boosting the rates of polystyrene recycling and advancing towards a more sustainable circular economy.

Mechanical Recycling

Recycling plastics mechanically entails cleaning the waste and then shredding it before melting it down to form new items which helps in conserving energy when compared to manufacturing the same products from scratch with raw materials.

rPS Recycling Mode

Several methods are utilized in rPS recycling including compacting foam and pelletizing processes.

Compressed Foam

Polystyrene foam can be squished down to take up space and be transported more efficiently and affordably for recycling purposes.

Pelletizing

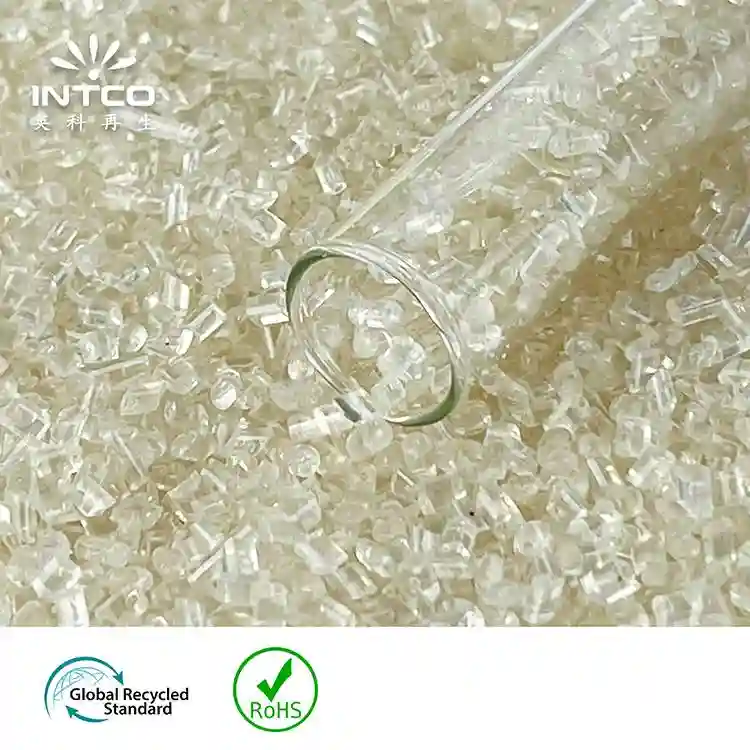

The polystyrene is turned into small pellets that serve as the foundation for creating fresh items.

r-PS Pellets

rPS pellets are an alternative to new plastic that can be used in different ways to help complete the recycling process.

Foam Trays

rPS can be recycled into foam trays suitable for food packaging, demonstrating a practical application of recycled polystyrene.

Foam Compressor

Foam compressors are beneficial in compacting waste to improve recycling efficiency and lower transportation expenses.

Intco Plastics: Your Reliable rPS Pellets Supplier

Intco Plastics and others play a crucial role in supplying pellets to various industries like food packaging and construction around the world to enable the utilization of recycled plastics in various industries, such as home decor and more.

FAQs

Why is reducing carbon footprint important?

Reducing our carbon footprint is essential for addressing climate change and protecting ecosystems to ensure a future achieved through the reduction of greenhouse gas emissions and the preservation of natural resources.

How does recycled plastic help reduce carbon footprint?

Utilizing recycled plastic aids in reducing the carbon footprint by conserving energy during production and cutting down on greenhouse gas emissions while also diminishing the necessity for materials.

What are the applications of rPS pellets?

rPS pellets are adaptable and find application in a variety of uses such as packaging for food and nonfood items they are also used in home décor elements and construction materials as well as in consumer electronics and other sectors. They can be incorporated into bottles, film textiles, and straps for purposes.